FERTILIZER FROM OILSEED EXTRACTS

Ralph Daniels, President, AGROTECH, INC.

AAPFCO Byproducts and Recycled Materials

Subcommittee Meeting, August 6, 1997

FERTILIZER

FROM

OILSEED EXTRACTS

Presented by Ralph Daniels, President, AGROTECH, INC.

at the AAPFCO Byproducts and Recycled Materials

Subcommittee Meeting, August 6, 1997

Oilseeds, as their name implies, contain high levels of oil in their seeds. The major oilseeds in world commerce are: canola (rapeseed), corn, cottonseed, peanut, safflower, soybeans and sunflower. Of these, soybeans account for fully one third of total world production. For the purposes of this presentation, soybeans and oilseeds may be used interchangeably.

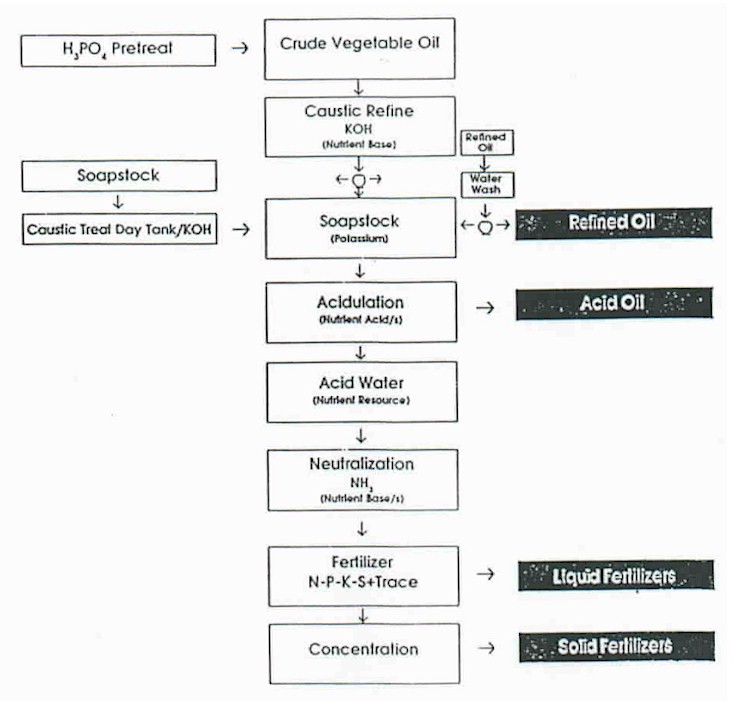

Soybeans are processed to yield two coproducts: soybean meal and soybean oil. The seeds are crushed and the oil is extracted with solvent. This maximizes the protein level in the meal. Since the solvent extraction is nonspecific, virtually the entire organic fraction in the seed is extracted with the oil. The primary non-oil components are phosphotides/phospholipids or lecithins, as they are commonly referred to, carbohydrates (primarily sugars), free fatty acids, protein fragments, color bodies (beta carotene) and mucilaginous substances or gums. After reclaiming the solvent, the extract at this point is known as crude vegetable oil/crude soybean oil.

In order to utilize vegetable oils for edible purposes (cooking oils, shortenings, mayonaisses and margarines), the non oil or "undesirable components" (natural organic compounds and mineral elements) must be extracted from the crude oil with alkali and the process is referred to as refining or purification.

In this process, the caustic or alkali refining method, a dilute aqueous solution of alkali (usually caustic soda, sodium hydroxide, Ca. 15%) is employed to react with the free fatty acids present to form soaps. The phosphatides and gums absorb alkali and together with the other organic and mineral substances which are dissolved or coagulated through hydration are collectively separated from the refined oil by means of a continuous centrifuge. This alkali extract of vegetable oil refining is commonly referred to as soapstock. The official NOPA designation is "refining byproduct lipid" (RBL) which was adopted in 1992 to more closely conform with AAFCO’s feed ingredient definition criteria.

Refining byproduct lipid (soapstock) can be directly incorporated into feeds or defatted meals however most is processed further to recover the fatty acids removed during refining. The recovery process is called acidulation as an acid, usually sulfuric, is used to split the soapstock emulsion into its oil and water component parts. After splitting, the oil phase is termed acid oil (AAFCO official definition - hydrolyzed vegetable oil - feed grade) and the aqueous phase is called acid water because of the low pH (1.5). Acid oil is a well known poultry and animal feed ingredient while acid water from the conventional technology in use constitutes a waste product.

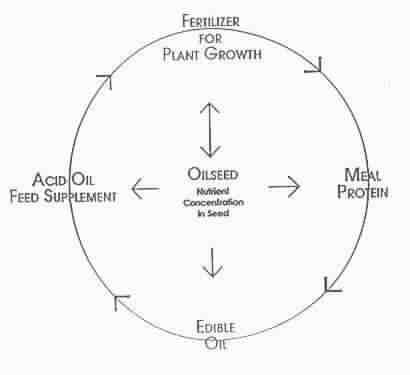

A new technology has been developed to produce acid oil from RBL/soapstock without any accompanying waste, i.e. a zero-discharge process. The technology, currently implemented in full commercial scale, creates a second, new coproduct from the acidulation process. All traces of the erstwhile waste are eliminated as the acid water is transformed into a multinutrient liquid fertilizer. It allows oilseed processing to become a closed loop, elegant nutrient recycling system.

·

NUTRIENTS ARE ABSORBED FROM THE SOIL, CONCENTRATED IN THE OILSEED, REMOVED DURING REFINGING, RETURNED FOR THE NEXT CROP CYCLE·

FERTILIZER BECOMES A RENEWABLE RESOURCE

Oilseed plants absorb nutrients from the soil and concentrate them in their seeds as energy for reproduction. Crushers extract the nutrients with the oil and refiners target them for removal as "undesirable constituents". They ultimately end up in the RBL or soapstock. Acidulation releases them for reuse in replenishing the soil for the next crop cycle. Virtually everything present in the seed extracted fertilizer is beneficial to plant propagation and soil fertility. Let me now discuss how a simple change or two in processing can promote such a revolution.

If caustic potash (potassium hydroxide) is used in place of caustic soda in the vegetable oil refining process, potassium soaps and potassium RBL/soapstock will be formed. When potassium RBL is acidified with sulfuric or other acids, singly or in combination, potassium salts of that acid are formed in the aqueous (acid water) phase rather than sodium salts. Using ammonia or arnmonium hydroxide in place of caustic soda to neutralize the potassium enriched solution further enriches it with nitrogen. In a series of acid-base reactions, the sodium which has little or no nutritive value and can be harmful to soils and plants has been replaced by potassium and nitrogen, both primary plant nutrients. Upon analysis the fertilizer solution will be shown to contain the three primary plant nutrients: nitrogen, phosphorus and potassium. The nitrogen is derived from natural seed protein and ammonia. The phosphorus is derived from natural seed phosphorus compounds (lecithins) as well as from food grade phosphoric acid which is added to the crude oil to facilitate lecithin extraction from the crude oil. Potassium is derived from natural seed sources as well as from the alkaline crude oil refining extractant, potassium hydroxide. The fertilizer solution also contains the three secondary plant nutrients: sulfur, calcium and magnesium. The sulfur is primarily derived from sulfuric acid which forms sulfate salts. Calcium and magnesium are entirely derived from the lecithin complexes naturally present in the seed. Most, if not all, of the trace element micronutrients are also present and are derived

directly from the seed. In addition, the solution contains soluble, beneficial organic matter which improves soil fertility and encourages microflora growth in the growing media. The nutrient content of the fertilizer solution is typically 2-3-4-2 (N, P2O5,K2O,S), although this can vary somewhat depending upon the seed and the refining extraction conditions.

This new fertilizer from oilseed extracts has been used to grow a wide variety of agricultural and horticultural crops and found to equal or outperform traditional commercial fertilizers in comparative fertility trials. (See Iowa State preliminary results, attached)

In summary, by modifying the chemistry of vegetable oil refining and the chemistry of RBL/soapstock processing, a new liquid multi-nutrient fertilizer can be produced from the natural nutrients extracted from oilseeds. We would appreciate the consideration of this subcommittee in officially recognizing oilseed extracts as bona fide sources of plant nutrients and its assistance in defining it for the trade.

Thank you for your kind attention. Are there any questions?